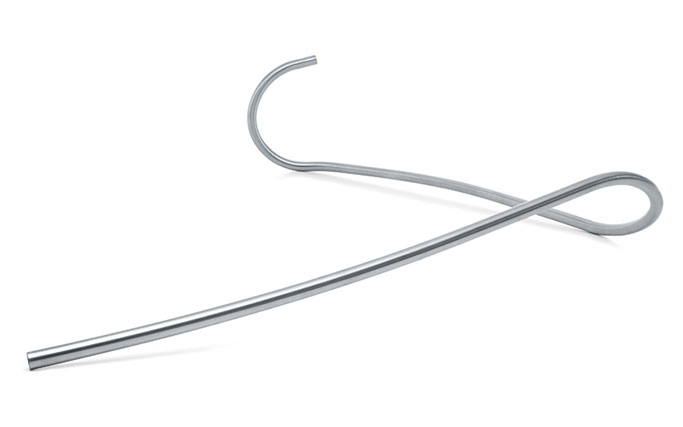

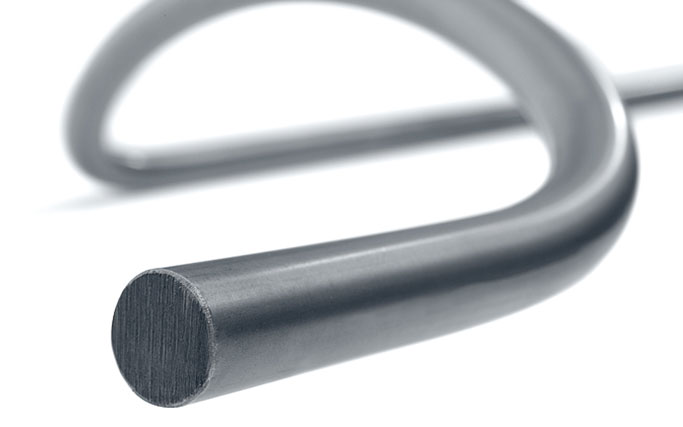

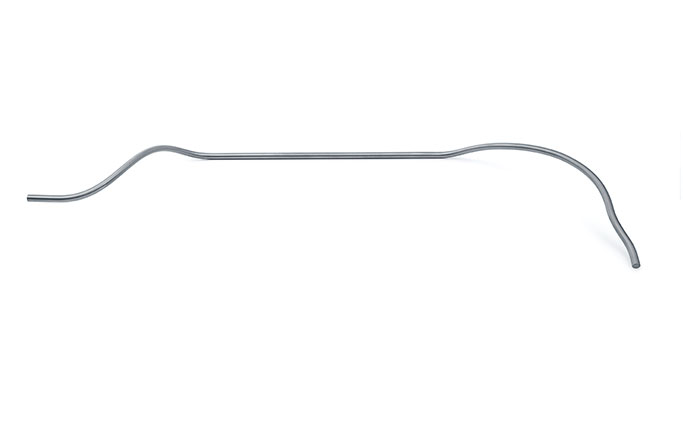

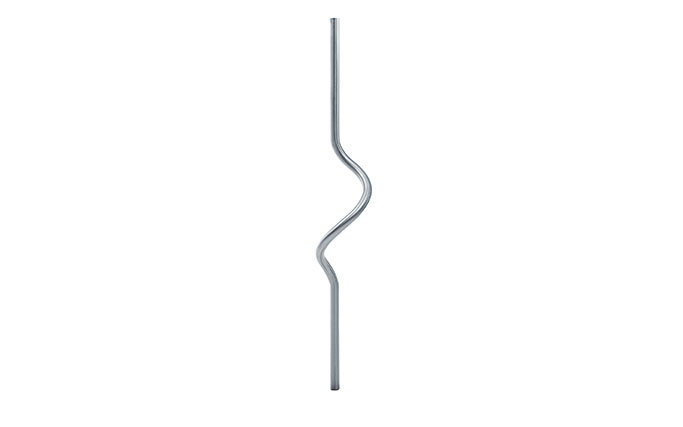

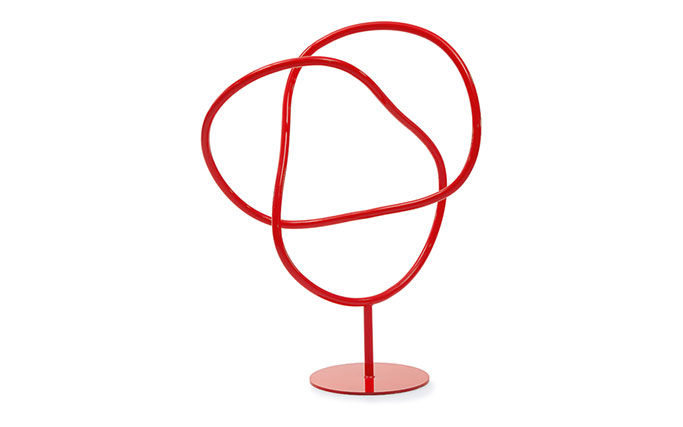

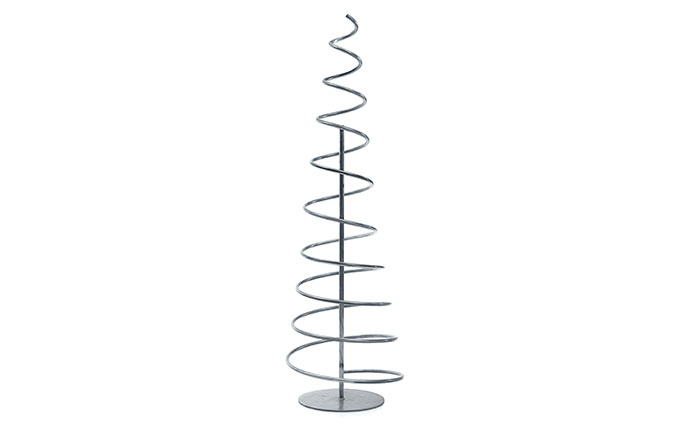

With our new free-form technology, we enable you to bend tubes as well as selected profile systems in almost any direction and radius. In this way, metals can be brought into unprecedented shapes – in architecture, design, industry or even in trade fair construction.

In the process, we not only implement creative forms – we in turn inspire architects, designers, planners and constructors to come up with completely new ideas. New objects and solutions emerge from this interchange.